Introduction:

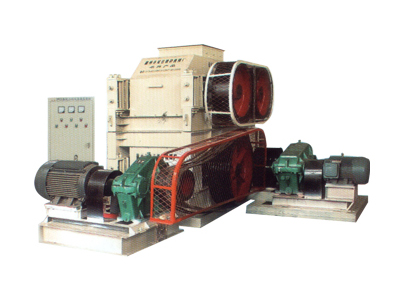

Roller crusher is mainly used for the crushing of medium-hard mines and rocks in cement, chemical, electric power, metallurgy, building materials, refractories and other industrial sectors, such as the secondary crushing and fine crushing of limestone, slag, coke, coal and other materials.

Roller crusher is mainly made up of roller wheels, roller support bearings, clamping and regulation devices and drive devices.

Working principle:

Roller crushers have a theoretical maximum reduction ratio of 4:1. If a 2 inch particle is fed to the roll crusher the absolute smallest size one could expect from the crusher is 1/2 inch. Roller crushers will only crush materials down to a minimum particle size of about 10 Mesh (2 mm). A crushes using compression, with two rollers rotating about a shaft, towards the gap between the rollers. The gap between the rollers is set to the size of product desired, with the realization that the largest feed particle can only be 4 times the gap dimension.

Features:

1. Average discharging size without blocking up.

2. Automatically sieve the material after crushing.

3. High efficiency and low energy consumption.

4. Good flexibility and operational reliability.

5. Full-sealed design and no dust pollution.

6. small vibration and low noise.

7. Removable shell which is convenient for daily maintenance and inspection of the machine.

Technical Parameters:

Series 2PG double roller crushers:

| Item |

Model No. |

Dimensions of roller

(Diameter×Length mm) |

Max. feeding size

(mm) |

Discharging size

(mm) |

Capacity

(t/h) |

Motor power

(kw) |

Rotary speed of roller

(r/min) |

Weight

(kg) |

| Double roller crushers |

2PG-3030 |

300×300 |

20 |

0-15 |

1.5-5 |

2x2.2 |

60 |

543 |

| 2PG-4025 |

400×250 |

32 |

0-8 |

5-10 |

2x5.5 |

200 |

1300 |

| 2PG-6040 |

600×400 |

85 |

0-12 |

4-15 |

2x11 |

120 |

3500 |

| 2PG-6090 |

600×900 |

85 |

0-12 |

8-35 |

2x15 |

120 |

8300 |

| 2PG-7550 |

750×500 |

100 |

0-12 |

10-40 |

2x15 |

80 |

9200 |

| 2PG-120100Y |

1200×1000 |

40 |

2-12 |

15-90 |

2x45 |

75 |

46400 |

| 2PG-120100T |

1200×1000 |

40 |

2-12 |

15-90 |

2x45 |

75 |

45400 |

Series 4PG four roller crushers:

| Model No. |

Dimensions of roller

(Diameter×Length mm) |

Gap between rollers

(mm) |

Max. feeding size

(mm) |

Capacity

(t/h) |

Motor |

Dimensions

(mm) |

Weight

(kg) |

Power

(kw) |

Voltage

(v) |

| 4PG-Y705 |

750x500 |

0-12 |

85 |

20-60 |

11/24/30 |

380 |

2760x3590x2650 |

19200 |

| 4PG-Y907 |

900x700 |

0-12 |

100 |

30-70 |

15/24/30 |

9000x4200x3200 |

27200 |

| 4PG-T907 |

900x700 |

0-12 |

100 |

30-70 |

30/15/22 |

4200x3200x3200 |

26000 |

| 4PG-Y1210 |

1200x1000 |

0-12 |

100 |

40-80 |

40/55/75 |

9610x5600x4240 |

67000 |

Series PGC toothed roller crusher:

| Model No. |

Dimensions of roller

(Diameter×Length mm) |

Max. feeding size

(mm) |

Max. discharging size

(mm) |

Capacity

(t/h) |

Motor power

(kw) |

Weight

(kg) |

Dimensions

(mm) |

| 2PGC-405 |

450x500 |

200 |

12 |

15-30 |

18.5 |

4300 |

2492x2160x760 |

| 2PGC-607 |

600x750 |

200 |

12 |

20-50 |

30 |

6800 |

3265x2780x1360 |

| 2PGC-610 |

600x1000 |

200 |

12 |

30-70 |

45 |

8700 |

4820x2887x1360 |

| 2PGC-909 |

900x900 |

300 |

12 |

40-80 |

45 |

13200 |

3974x2827x1650 |

| 2PGC-1012 |

1000x1200 |

300 |

12 |

60-120 |

55 |

13500 |

4820x2860x1450 |

| 4PGC-406 |

400/380x600 |

300 |

12

25 |

30-60

50-80 |

18.5/22 |

7100 |

2355x1805x1450 |

| 4PGC-412 |

400/380x1200 |

300 |

12

25 |

50-90

80-150 |

75 |

9600 |

3650x1805x1450 |

| 4PGC-717 |

760x1730 |

300 |

12

25 |

180-300

250-400 |

3×75 |

17600 |

5770x1920x1860 |

| 4PGC-810 |

800x1000 |

300 |

12

25 |

60-100

90-125 |

75 |

16000 |

5270x1970x1920 |

| 4PGC-1008 |

1000/1100x800 |

300 |

8

13

25 |

100-140

130-180

170-260 |

55/75 |

21000 |

4614x1824x2340

(4614x3834x2340) |

|